Additive Manufacturing, better known as 3-D printing, is one of the fastest growing technology sectors.

It’s a printing process where plastic or metal parts are built-up layer by layer.

In this week’s Exploradio, we look at where the industry is headed and how Northeast Ohio is building itself into the nation’s additive leader.

Around 200 people have gathered to hear the latest advances in 3-D printing at the recent Additive Manufacturing Cluster of Ohio Conferencenear Cleveland. It's also a chance for local businesses to display their wares.

Rick Pollack is founder of MakerGear. He sells machines that print plastic parts. I first met him nearly a decade ago when he was making 3-D printers out his home, with a full production line in his living room.

“Ten years ago desk-top 3-D printing was really esoteric," says Pollack, "we were making machines out of plywood. They were really just hacker-fun kind of machines.”

Like the industry, Pollack’s company has grown. He now has a factory in Beachwood. His customers include schools, libraries, and a dental lab, “They’ve got like 70 of our machines running all the time printing teeth for them to do their work on.”

But when asked where he’ll be ten years from now, he acknowledges, "I don’t know... the market’s gotten super competitive.”

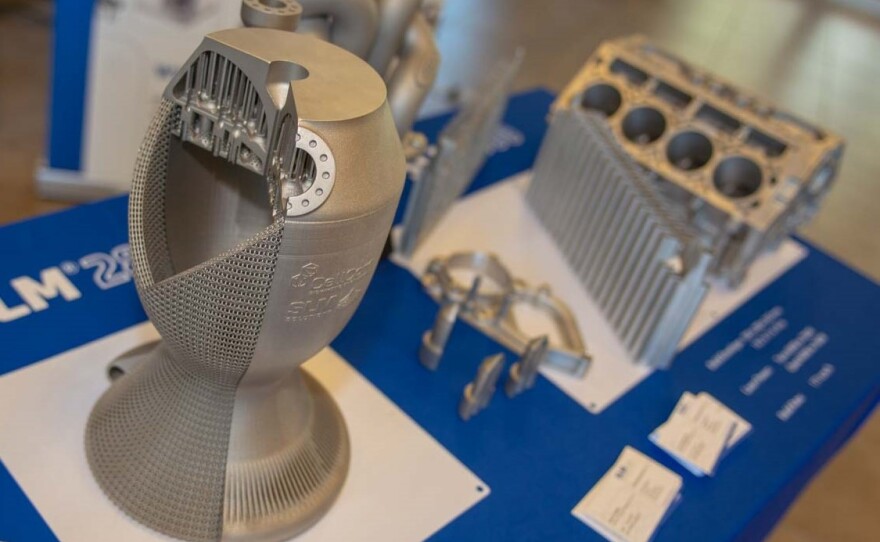

The future is metal

Additive manufacturing is at a cross-roads, according to presenter Mark Barfoot, director of additive programs at EWI, a Columbus-based consulting firm.

He’s says a decade ago plastic was the word in 3-D printing, “Now metal has come to that point.”

He says the aerospace, automotive and medical industries are beginning to see the benefits of 3-D printing metal components, and, “we’re moving into the meat and potatoes of actually doing production parts.”

In his presentation, Barfoot described dozens of new techniques for 3-D printing in metal. The most promising one, he says, is binder jetting which prints parts out of a bed of powdered steel, other alloys, or even sand.

The concept is simple, according to Barfoot, “you spread a layer of powder and use a regular inkjet print-head, spray out a binder that holds and coagulates that powder together, and when you’re done you brush off that powder and put it in a sintering oven to fully sinter it and get it fully dense.”

Voila! You’ve got a metal part that couldn’t be made with traditional casting.

Making manufacturing cool again

Barb Ewing is CEO of the Youngstown Business Incubator (YBI) and one of the organizers of the conference.

She’s making sure local manufacturers know that this new technology is ready for the marketplace.

“We go out and work with industry," says Ewing, "to help them understand how to integrate additive into their operations today, not a decade from now, today.”

Youngstown is home to the nation’s first additive manufacturing trade institute, America Makes, and Ewing says it, along with her group have bold goals for the region.

“What you see coming out America Makes and Northeast Ohio is really a reinvigoration of manufacturing and making manufacturing cool again,” she says.

Youngstown has become the nation’s hub for 3-D printing, according to Ewing, through the combined efforts of America Makes, YBI, and Youngstown State University.

Erin O’Donnell, director of partnerships at America Makes, agrees to show us around.

Why America needs Youngstown, Ohio

YBI's additive incubator is housed in the historic home of the Youngstown Vindicator, now known as Tech Block Building 5. O'Donnell says it's gone from a building used for printing in two dimensions to printing in three dimensions.

Inside we find a vintage linotype machine, a 20th century relic among state-of-the-art 3-D printers that line the former newspaper production floor.

Several minivan-sized machines are housed in special climate controlled rooms. These units can print parts in metal and even ceramics.

A California company recently moved its production here. Fitz Frames makes custom eyeglasses for kids.

O’Donnell says America Makes, the Youngstown Business Incubator, and Youngstown State University have created an additive manufacturing ‘ecosystem’.

“When you really look at where additive is happening and where to go to get experience or knowledge," she says, "you’re coming to Youngstown, Ohio.”

Attracting and keeping talent

That may be true. Even some of the region’s big players, Goodyear, Parker Hannifin, and Lincoln Electric are dipping their toes into additive manufacturing with help from the consortium.

But several hurdles remain when it comes to adopting additive printing for mass production, including higher unit costs, slower speeds, and the lack of a unified set of quality standards.

A recent report shows one of the main obstacles to building an additive manufacturing industry in Northeast Ohio is keeping the talented engineers we produce close to home.